Manufacturing is a new magnet for tech-talent. One LA-based ‘Factory-of-the-Future’ is banking on it

Manufacturing’s workforce challenge is to get to the other side, to a promising future where graduates from the trade and higher education flash skills that match the workforce needs of a modern, high-tech industry.

We’re not there yet, but the fruits of a decade of workforce advocacy, diminishing returns from university degrees, tech-industry malaise, a corporate shift to localize production — and more — are combining to supercharge interest in manufacturing.

And something else is happening. Manufacturing is capturing the imagination of “knowledge-based” talent. Technologists are taking note. And they like what they see.

Matt Sand is channeling a technology background and Air Force service into Avalon MFG, a high-tech fabricator on the leading edge of automation. “I was a computer science major. I was a software engineer for the first four or five years of my career. We’re not from the manufacturing world per se,” says Sand, “but we’re attracted to manufacturing because of the opportunity — and because it’s cool.”

And for emphasis: “It’s cool stuff.”

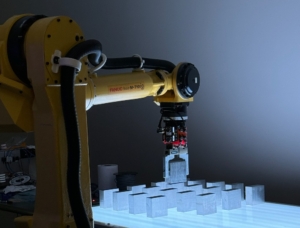

In Los Angeles, Sand’s ‘factory-of-the-future’ is startling in scope. “The vision for the company and for the factory and technology is to basically have a truck pull up with raw material on one side of the factory and finish parts going out the other side of the factory. And to do that without any human intervention,” he explains. “I’m not saying humans aren’t around the factory, but humans aren’t working directly on the parts.”

A decade ago, Sand’s vision might have been threatening to some — the last gasp of a sector already reeling from millions of jobs losses. Today, it feels less dystopian and more an evolution of sorts. Today, manufacturing’s too important, with a new allure.

“I mean, this is not your grandfather’s machine shop. This is high technology being used to make a significant impact in society and you know, unlike most software engineering where at the end of the day you have a bunch of code on a hard drive that could be erased and your life’s work lost in the blink of an eye,” he says. “Here we’re making real parts, parts that are flying and supporting the U.S. warfighter. It’s really exciting to be a part of that.”

Sand sees other benefits. “This changing of the guard, this paradigm shift with new technology is bringing new talent into the industry that looks at the problem slightly differently. I think there’s less interest from guys like me in just building a machine shop and just making parts. There’s nothing wrong with that, and I know a lot of guys who make a great living doing that,” he says. “It’s great, but to me, the opportunity that I see is the idea of reinventing the machine shop. Moving away from a commodity low margin business to something that could be a scalable business with decent margins.

“You always have the cost pressure. So, I don’t think you’re going to have Google-like margins ever, but you can have decent margins. What we’re doing is hard and not easy or cheap to replicate. But we’re building something with a sizable moat around it; it’s defensible. And so that’s what attracted me — and it’s why I’m doing it.”

Sand’s vision will require a different workforce; technology-meets-fabrication in his factory-of-the-future. “I work with guys here who have, you know, 10-15 years set-up experience and there’s still a big gap between their knowledge of setting up and of programming in a CAD environment,” he says.

We’re realists here, and the reality is that Sand’s shop is an outlier, and that manufacturing still needs set-up pros. We can’t stop supporting — and training — a 2025 workforce.

Not only that, but Avalon MFG is also angling for high-volume, standardized parts that fit the procurement model of a narrow range of aerospace buyers. Not that outputs won’t change, but today, America’s legion of jobs shops and machinists rely on human intervention to ideate, to prototype, to set-up and manufacture in small quantities or at scale — for a diverse mix of industry buyers.

But by capturing the imagination of Sands and his techno-ilk, manufacturing has also achieved a small but significant win. We’ll take a closer look at Avalon MFG’s operations and get a status report on Sand’s factory-of-the-future, next time.

Bart Taylor is founder of MFGInsider and executive director of the Greater Houston Manufacturing Association. Reach him at baylor.media@gmail.com.