2020 CMA Preview: Innovative Product of the Year

Innovation comes in many forms, and in this inaugural Colorado Manufacturing Award for Innovative Product of the Year, companies were asked to submit products distinguished by design-centered manufacturing, with the following criteria:

- Integration: degree to which manufacturing considerations are incorporated into the product design.

- Advanced processes: the use of advanced manufacturing processes

- Leading-edge visual aesthetic

- Innovative functionality

Guerrilla Gravity

Consumer product, cycling frames

Denver’s Guerrilla Gravity has earned a reputation both as an innovative cycling manufacturer and outstanding business, flashing important operational achievements including a $250,000 Advanced Industries grant from the Colorado Office of Economic Development and International Trade.

Yet a tightly integrated design-to-manufacturing process is the company’s calling card. Highly configurable designs, inspired by local talent, take into account the unique challenges of frame manufacturing. The use of proprietary carbon-fiber technology, in-house molds and printed parts are among the innovations that enable manufacturing of cycle frames in Denver, tipping over an industry paradigm that for decades have sent cycling OEMs offshore.

The improved manufacturability of the final product is further reflected in leading aesthetic functional attributes of the product, like impact resistance in demanding terrain.

CompanyWeek profile: https://companyweek.com/article/guerrilla-gravity

TEI Rock Drills

Commercial product, HCC10X Control Unit

The innovative HCC10X control unit was inspired by a customer request to improve safety on the job site.

The company’s successful response started with a design process driven first by meetings with relevant manufacturing departments to address design concerns and simplify the manufacturing process. Design engineers were then available to shop managers once production started, to address issues that were missed in the concept phase.

The product’s rapid development required the use of additive manufacturing to meet the tight deadlines of the project. A working prototype was operational within two weeks, bypassing a longer lead time required with traditional tool and die processes.

The control unit is also functional with multiple excavators, enabling customers to utilize the product with rented equipment, potentially saving thousands of dollars in transportation costs alone.

CompanyWeek profile: https://companyweek.com/article/tei-rock-drills

Eldon James

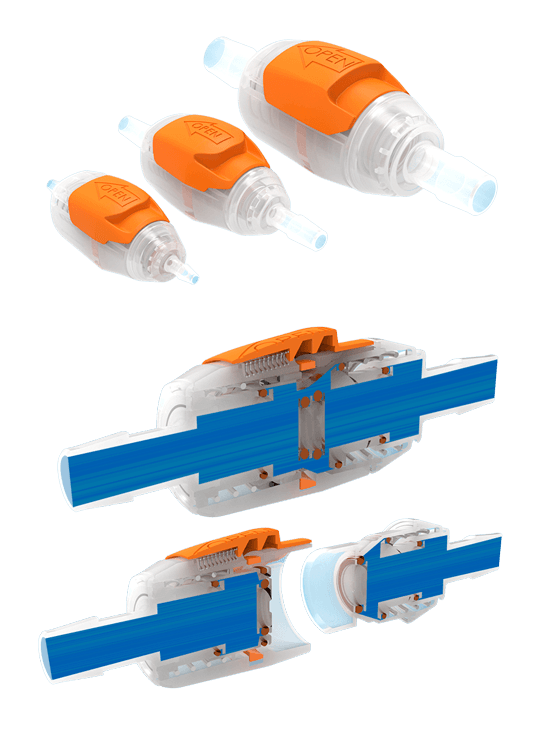

Commercial product, SeriesLock disconnect coupler

The notable medical device manufacturer has been awarded multiple patents for spring-free couplers that improve user functionality while maintaining high levels of flow with lower line pressure.

A highly integrated design-to-manufacture process is distinguished by the use of additive manufacturing to rapidly prototype products, facilitate customer feedback, and move products to final production.

The shortened product manufacturing cycle enables a robust design process that results in enhanced usability, including improvements in latch mechanisms and mating features, that have set the product line apart.

SeriesLock innovations have also enabled the company to diversify from the biomedical industry to life science, automotive, and industrial food and beverage applications.

CompanyWeek profile: https://companyweek.com/article/eldon-james

The winners of this year’s Colorado Manufacturing Awards will be announced online from 2:30 to 5 p.m. on Aug. 6, 2020. REGISTER HERE>