Food brands and co-manufacturers retreat from the bleeding edge to survive and thrive

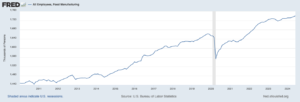

Food manufacturing is America’s great but underappreciated industrial success story, a tale of workforce growth fueled by innovation that’s even more impressive considering the full-tilt automation underway throughout the sector. Against a tide of robotics, job growth in food continues to be a highlight:

But as much as innovation has been a catalyst, the pace of change has slowed. “Breakthrough” product developments have given way to incremental change, to “safe” innovation in what’s become a more risk-averse business and product landscape. And for those whose job it is to go-to-market with new products or processes, to find the next big thing in an industry that’s produced game-changing results year after year, fast growth ahead is less certain.

Fresca Foods’ Allie Brimlow joined Colorado’s market-moving co-manufacturer in 2016 to in part manage the myriad opportunities coursing through the market. “A huge part of why I was hired was to help the sales and marketing team formalize and monetize some of our services around innovation. We were doing so much, going full bore,” Brimlow says. “We were doing a lot of free product development — new product ideation — and were proactively presenting new concepts that fit our manufacturing capabilities. So much so that I was brought on board, the mindset of like ‘wait a minute, these are services that we are providing right now for free that we should really monetize,’” she laughs.

“By 2018 -2019, we’d also become the innovation arm for big food companies specifically in the natural and organic space. They’re really good at doing large scale production of conventional foods, but when it comes to doing innovation outside of that, they struggle to move quickly and manage some of the challenges that come with the natural and organic space — like allergens, certifications, and things like that. So, they looked to companies like Fresca that could help that and be an external source of that innovation,” she adds.

COVID changed the game. “Since the pandemic, I feel like innovation has been a lot more safe, a lot simpler. Pre-pandemic, we were doing things like upcycled veggie jerky, really ‘out-there’ and interesting food products — more bleeding-edge innovation. Today, a lot of the innovation we see is different, more ‘can you take our bar and put a drizzle on it?’ Our hypothesis, and what we’ve heard from our brand partners and industry friends, is that consumers are craving familiarity, things that are comfortable, that are familiar, given all the other uncertainty in the world,” Brimlow says.

It seems a more comfortable place for industrial-size, consumer packaged goods companies, and less so for the small operators who, in the last decade, have made a mark by coming to market with novel ideas. “I think smaller brands have always been the more breakthrough innovators,” Brimlow confirms. So where does that leave the “innovation arm” of the industry?

“I think the path for smaller brands to scale, to muscle their way through to national distribution, has become really challenging,” Brimlow says. “As the product window has narrowed, there’s also a lot of pressure right now on ingredient and labor costs — especially where we operate, in Colorado. I mean, the number of innovative ideas that have been scrapped in the last couple of months that had chocolate in them is nuts,” she says. “There will be a decline in the launches of anything chocolate next year because of prices.”

Moreover, “everything is more expensive when you’re just getting started — smaller quantities mean ingredients are more expensive, the cost to make your product is more expensive, packaging is more expensive, and you’re oftentimes ordering more than you need just to hit target product cues,” she says.

Yet attend any industry function — in the natural food mecca in Boulder, Colorado, or elsewhere —and the energy and optimism seem as high as always. Brimlow is no different.

“For one, if you had a brand in-store and were able to stay on the shelf through the pandemic — a lot of those brands are experiencing incredible growth,” she says. “There’s also this interesting dichotomy that — despite inflation and supply chain and challenges related to capital — in the ‘safer’ innovation category, as I call it, there’s still a lot of growth and health, especially in the natural and organic industry.

“And I do think that the pendulum will swing back towards more breakthrough innovation. From my perspective, I think the only thing holding it back is the economy and the kind of uncertainty that consumers are feeling,” she adds.

As an early mover in Colorado’s dynamic food manufacturing ecosystem, Fresca Foods rode into the pandemic as a market leader and has emerged in an enviable position. “Fresca is growing like crazy this year. We literally cannot keep up. Most of our systems are at capacity,” Brimlow says. “We’re looking at our next building, expanding our footprint and capacity on two of our core platforms — bars and granola. We see a lot of growth just on the manufacturing side,” she notes. And innovation is key. “You can’t just do one thing, you have to always be innovating, product life cycles are tricky. They will fade over time.”

But she also acknowledges a manufacturing gap that makes it hard for smaller brands to find right-sized manufacturing. “As you embrace innovation, you’re investing in equipment. The most efficient way to use that equipment is just by running it as much as you can as often as you can, so there’s a lot of incentive for contract manufacturers to ‘go big,’ to lean into the bigger volumes. The efficiencies are there. It’s been amazing to watch the company grow, but it also means we’re outgrowing some of our smaller brands,” Brimlow explains.

It seems only a matter of time before local and regional co-manufacturing realigns with a newly energized, post-pandemic food sector, where small and middle market brands have better options. Even today, the resources may be available, just hard to find.

What Brimlow, Fresca Foods, and other influential brands and co-mans are doing is leaning in to support the overall health of a sector that’s poised for post-pandemic growth. Join Allie Brimlow, Awakened Foods’ Jeff Schmidgall, Bobo’s TJ McIntyre, Boulder Organic Foods’ Greg Powers, Cappellos’ Ben Frohlichstein, others guests, and me, Monday July 15, for a mid-day Colorado Proud webcast to discuss how food innovation goes-to-market in today’s “normalizing” economy.

Bart Taylor is a Moss Adams BDE and contributor to MFG Insider. Reach him at bart.taylor@mossadams.com